Grain storage is a key factor in the efficiency of the agri-food supply chain. Choosing the right solution can significantly impact profitability, product preservation, and long-term sustainability.

Among the most widely used options — metal silos, concrete silos, warehouses, and grain bags — metal silos are increasingly standing out for their efficiency, durability, and adaptability. This article compares them to concrete silos and highlights their main advantages.

Advantages of metal silos over concrete silos

1. Manufacturing Process and Quality Control

Metal silos are manufactured in controlled factory conditions, ensuring precision, consistency, and compliance with strict quality standards.

In contrast, concrete silos are built entirely on-site, making them highly dependent on environmental factors (weather, concrete supply, labour skills. This introduces more risks, extends execution times by up to 30%, and often leads to inconsistent results.

2. Design, Installation, and Structural Flexibility

Metal silos can be built with larger diameters, maximizing total storage volume.

While concrete silos can reach greater heights, their narrow profile limits capacity and complicates grain discharge.

Accessory integration such as doors, ladders, walkways, or aeration systems is simpler and more cost-effective in steel silos.

Additionally, steel has greater structural flexibility, providing better seismic performance than brittle concrete in earthquake-prone regions.

3. Grain Preservation and Inner Surface Quality

A less-discussed yet crucial advantage is the smooth interior of metal silos, which prevents damage to the grain.

Concrete walls are typically rougher and can abrade grain during loading and unloading, increasing breakage and reducing quality—particularly in sensitive crops like rice or corn.

4. Durability: The Magnelis® Breakthrough

Concrete silos have traditionally been seen as more durable, mainly due to concerns about steel corrosion in harsh environments. However, the introduction of Magnelis®, a next-generation Zn-Al-Mg metallic coating, has completely changed this perception:

Magnelis® provides up to 3–4 times more corrosion resistance than standard galvanization.

It significantly extends the lifespan of steel silos, even in coastal, tropical, or high-humidity environments—often outperforming concrete structures in durability.

It also minimizes maintenance needs, unlike concrete silos which are prone to cracking and spalling over time.

5. Ventilation and Temperature Control

Metal silos allow for more efficient ventilation due to their wider geometry and shorter grain columns.

In tall concrete silos, the deeper grain mass increases compression and heat buildup, complicating aeration and raising spoilage risks. Airflow is also less efficient due to the non-linear relationship between grain depth and ventilation power.

6. Foundation and Soil Requirements

Metal silos are lighter and exert lower pressure per square meter, making them ideal for sites with lower soil bearing capacity.

Concrete silos, by contrast, require deep, reinforced foundations, which increases construction complexity and costs by up to 25%.

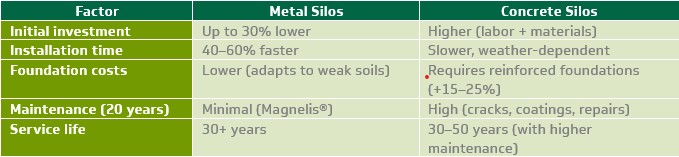

7. Cost Comparison

8. Sustainability and Adaptability

Metal silos are 100% recyclable, contributing to circular economy strategies.

Their modular design allows for easier future expansion, relocation, or dismantling—unlike permanent concrete structures.

While concrete silos may be suitable for very specific use cases (such as extremely limited space or very tall configurations), modern steel silos with Magnelis® coating offer clear advantages:

√ Faster and safer installation

√ Superior grain protection

√ Enhanced seismic performance

√ Greater corrosion resistance

√ Lower initial and lifetime costs

At Silos Córdoba, we turn these advantages into real-world solutions, designing and building metal silos that protect your grain today and ensure the profitability of your business tomorrow.